Looking for a reliable Supplier of Weigh Metrix Filling Machine in Karnataka?

Welcome to Satchit Engineering, your trusted partner in precision filling and packaging solutions.

We specialize in offering advanced, high-performance Weigh Metrix Filling Machines designed to meet the needs of a wide range of industries including food,

agriculture, chemicals, and construction.

Our Manufacturing unit is located in Ahmedabad, Gujarat, India.

🌟 About Satchit Engineering

Satchit Engineering is a reputed name in the industrial machinery supply sector in Karnataka. With a commitment to quality, innovation,

and customer satisfaction.

We provide state-of-the-art packaging and filling machinery that increases productivity and reduces manual errors.

Our expertise, paired with prompt after-sales service, has made us the preferred supplier across Karnataka.

Whether you’re a small-scale producer or a large manufacturing unit, our Weigh Metrix Filling Machines offer unmatched

precision and durability.

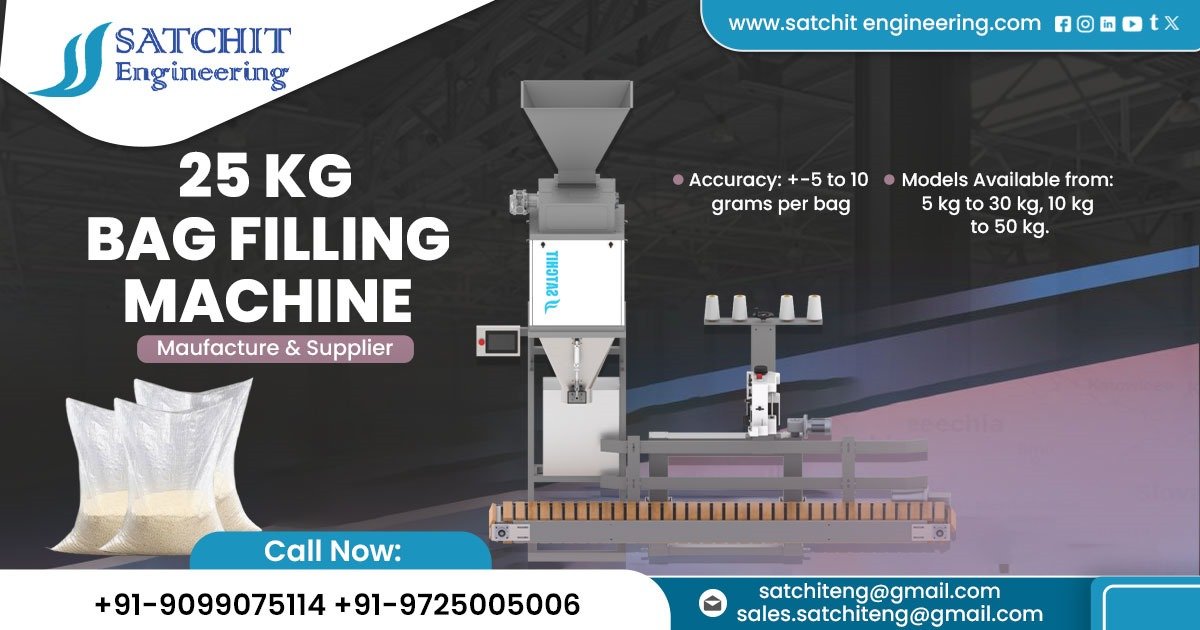

Specifications Of Bag Filling Machine (SE-500)

Model: SE-500 (10 KG TO 50 KG)

Packing Capacity: 10 KG TO 50 KG

Type: Semi-Automatic

Weighing System: Servo Based Mechanism

Packing Material: Rice, Wheat, Granules, Beans, Plastic Balls, Spices, Wheat,

Sugar, Fine Particles, etc.

✅ Features of Weigh Metrix Filling Machine:

Our Weigh Metrix Filling Machines come equipped with the latest technology to deliver high-accuracy filling solutions. Key features include:

- High Weighing Accuracy: Advanced load cells ensure precise weight control.

- Stainless Steel Construction: Corrosion-resistant body suitable for hygienic operations.

- Easy-to-Use Interface: User-friendly control panel for quick operation and adjustments.

- Adjustable Filling Speed: Customize filling rates to suit your product type and production volume.

- Compact and Sturdy Design: Space-saving and built to last under tough conditions.

- Auto Tare Function: For consistent weight measurement across batches.

- Energy Efficient: Designed to reduce power consumption.

⚙️ Work of Weigh Metrix Filling Machine:

The Weigh Metrix Filling Machine is a semi-automatic or fully automatic unit that precisely fills bulk materials by weight. It works in the following steps:

- Material Feeding: Material is fed from a hopper or silo.

- Weighing: The load cell measures the target weight.

- Filling: The machine fills bags, containers, or pouches with exact weights.

- Discharge: After the filling is complete, the package is released for sealing or further processing.

📦 Uses of Weigh Metrix Filling Machine:

These machines are widely used across industries, such as:

- Food Processing: Grains, pulses, spices, sugar, salt, flour

- Agriculture: Seeds, fertilizers, animal feed

- Chemicals: Powders, granules, additives

- Construction: Cement, sand, fly ash

- Plastics: Granules, masterbatch, resin

FAQs:

Q1: What is the capacity of your Weigh Metrix Filling Machines?

A: We offer machines with various capacities ranging from 5 kg to 100 kg depending on customer requirements.

Q2: Can I use this machine for powdery materials?

A: Yes, our machines are compatible with both granular and powder materials with appropriate feeders.

Q3: Do you offer installation and training?

A: Absolutely. We provide complete installation, commissioning, and on-site operator training.

Q4: Is the machine customizable?

A: Yes, we offer customized filling solutions based on the material type and production volume.

Q5: What areas in Karnataka do you supply to?

A: We serve all major cities and industrial areas in Karnataka including Bangalore, Mysore, Mangalore, Hubli, Belgaum, and Tumkur.

Satchit Engineering is a Supplier of Weigh Metrix Filling Machine in Karnataka including locations in Bangalore, Mysore, Hubballi-Dharwad, Kalaburagi, Mangalore, Belagavi,

Davanagere, Bellary, Vijayapura, Shimoga, Tumkur, Raichur, Bidar, Udupi, Hospet, Gadag-Betageri, Robertsonpet, Hassan, Bhadravati, Chitradurga, Kolar, Mandya, Chikmagalur,

Gangavati, Bagalkot, Ranebennuru, and Arsikere.

For more information and inquiries, feel free to contact us.

View Product: Click here